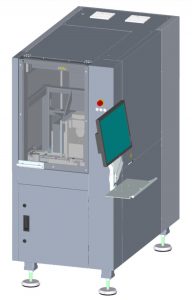

Inline Hybrid

An automatic inspection solution for boards

Our Inline hybrid solution is our automatic solution to inspect ceramic boards up to 6″ x 6″ in a super high speed solution. We can use backlight and toplight for the inspection and can find defects like excess paste, missing paste, smearing, narrowing, mouse bites, holes, via covering, sprayers, bleeding of paste, contamination, print shifts, substrate shrinking, screen aging, etc, and it differentiates between random and serial defects.

The materials that are inspected are usually conductor materials (like silver or silver palladium), resistor paste, cover glass, adhesives, gold, etc., and it detects all defects that are relevant in modern fine line screen printing. The tendency goes to even finer structures. On prints with less than 50 µm line widths, inspection with the human eye is not possible or very unreliable. The STRATUS VISION AOI systems can inspect a 4″ x 4” substrate in less than 4 seconds and find defects starting at 5µm. Inspection of wet (directly after screen printing) or dry surfaces is standard. System can be delivered with flipping (for back side inspection) and/or Magazines and Cassette Automation.

Length x Width x Height: 1445 mm x 800 mm x 1788 mm

Weight: 600 kg

Color: RAL 9003

Welded Steel frame

Granite base

Flexible Monitor arm

Voltage: 110V AC to 240V AC

Current: 4.8 Amps to 2.2 Amps

Frequenzy: 50 to 60 Hertz

Network: Ethernet RJ45

Air: 6 bar

Air consumption: 40l / min

Camera: Areascan, Linescan and 3D

Resolution: 1µm to 15µm

Lens: Telecentric, Bicentric

Operating Temperature: 18.5°C +/- 8.5°C

Operating Humidity: 50% +/- 25%

Power Consumption: 0.5kW average