Fast Fire Furnace

Muffle-less Furnace for low-cost Operation

Atmosphere Control

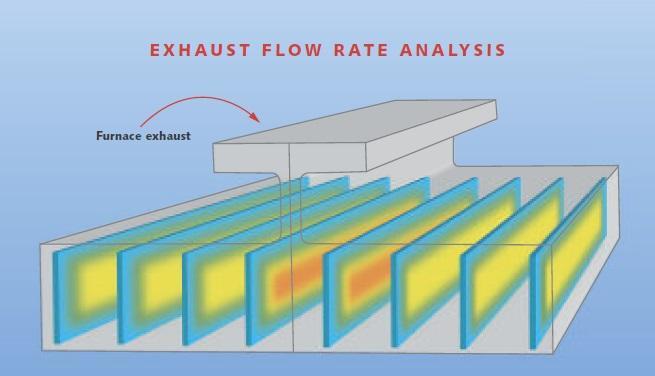

BTU’s Fast Fire conveyor furnace features precise atmosphere control of the critical process parameters within the furnace. The firing furnace gas panel is designed for ease of use while minimizing operator intervention. Firing section atmosphere is introduced at the cooling section and flows counter to product travel. Process emissions are removed from the process chamber via independent, venturi-driven, exhaust plenum assemblies. The plenum assemblies extend across the entire width of the process chamber for uniform extraction of burnout gases. Entrance and exit gas curtains are provided with top and bottom ratio flow control valves.

BTU’s Fast Fire Furnace combines the best of both worlds with precision temperature control and low-cost operation. Whether you’re manufacturing thin-film circuits, passive components, precision resistors, component termination, or many other applications requiring exact atmosphere and temperature control, BTU provides the Fast Fire furnace system.

BTU’s Fast Fire, due to its muffle-less design, offers reduced power usage by allowing rapid heating and cooling between uses. Further, the design supplies excellent atmosphere flow for binder removal, coupled with precision temperature control to meet the process control needed in thick film firing. In addition to the standard air atmosphere configuration, Fast Fire is available for nitrogen atmosphere operation. For cost-effective high-temperature processing in air or nitrogen Fast Fire is the best choice.

Benefits of the Fast-Fire’s muffle-less design:

- – Very short heat-up and cool-down times

- – No expensive muffle replacement

TEMPERATURE CONTROL

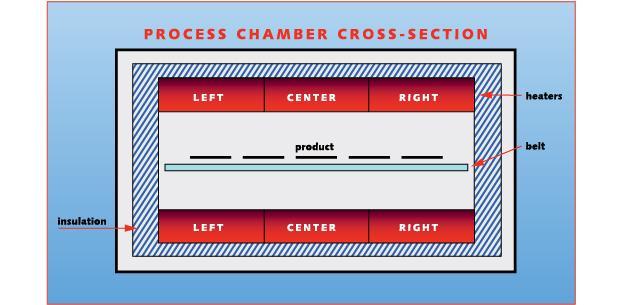

BTU’s muffle-less belt furnace maintains precision control by utilizing segmented heated sections that are programmed and controlled by BTU’s proprietary Wincon, Windows-based, furnace control system and Intellimax furnace controller.

- Left/center/right independent power trim standard on 25″ belt widths

- +/- 2°C across conveyor belt uniformity typical

- +/- 1°C across conveyor belt uniformity achievable in peak zones