Inline MVI Metrology

An automatic inspection & measurement solution for foils or boards

Our Inline MVI Metrology solution is our automatic solution to inspect and measure substrates. The systems main purpose is automated dimensional and positional measurement of general features and interposers on foils, boards and other materials. During a automated measurement inspection the system can also inspect for surface defects.

Our system requires very little setup and is mainly CAD based to ensure ease of use and simple product adjustment. The measurement is then performed on all structures with a very fast Stratus Vision patented scanning technology. During the measurement process the system can also detect all defects that are relevant in modern electronic production. Our solution can measure up to 10.000 interposers per second for diameter, position, roundness and save those values to the database to analyze production.

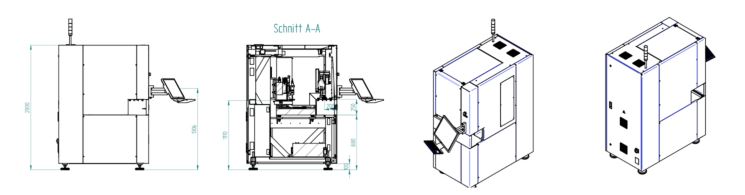

Length x Width x Height: 1445 mm x 830 mm x 2548 mm

Weight: 850kg

Color: RAL 9003

Welded Steel frame

Granite base

Flexible Monitor arm

Voltage: 110V AC to 240V AC

Current: 4.8 Amps to 2.2 Amps

Frequenzy: 50 to 60 Hertz

Network: Ethernet RJ45

Air: 6 bar

Air consumption: 40l / min

Camera: Areascan, Linescan and 3D

Resolution: 1µm to 15µm

Lens: Telecentric, Bicentric

Operating Temperature: 18.5°C +/- 8.5°C

Operating Humidity: 50% +/- 25%

Power Consumption: 0.5kW average