Laser Trim Inspection

Automated Inspection according to size, distance from the conductor and other criteria

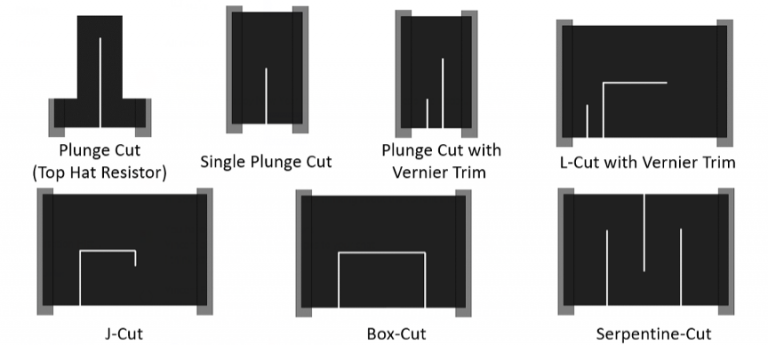

In screen printing resistors are usually printed on ceramic substrates using specialized inks such 10,100, 1000 up to 100MOhm. Varying the geometry of such resistors, any value could be achieved. Laser trimming of the resistors on ceramic circuits allows to burn away small part of them and is a required step in achieving the desired resistance value. The measured value of the resistance depends from its size, length, material and a partial cut of it can help to increase the resistance value. Laser cuts trimmed on the resistors could have different sizes as shown in the picture to the right.

In our inspection solutions we have been inspecting trimmed resistors for many years and it has been a core requirement of our solutions from the beginning. With our newest software solutions we are now able to inspect the laser trimmered resistor cuts according to their length, size, distance from the conductors and other acceptability criteria requested by the customer. This is a major improvement to the current processes and allows for integrated 100% control of all trims for their plausibility. Adding this capability greatly improves the process output and analysis and can help identify trim issues at a much earlier stage.

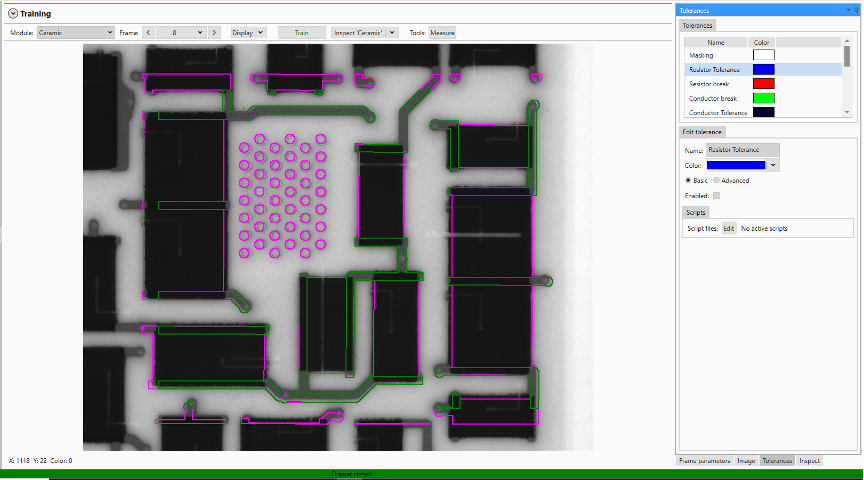

The frist fundamental step is to use Cad in our software SPIN and to have the right overlap between the Cad’s layers and the acquired image in order for it to be properly inspected. Through the information from the CAD the system automatically knows what areas are resistor and identifies these areas, even if they have shifted, in the acquired images.

Get more information about our Laser Trim Inspection from one of our Consultants

Next using the proper algorithms that are part of our software suite to detect laser trimms we can control for the following specifications:

- Shape

- Length

- Width

- Distances from each other

- Distance from the border of the resistor

- Distance from the conductors

- Serpentine laser trimmer cut

- Impurities and particles in the cut area

- Other acceptability criteria requested by the customer

These specifications can be different for different resistor types and a special set of rules can be applied for thin film PT100 trimmed sensors.

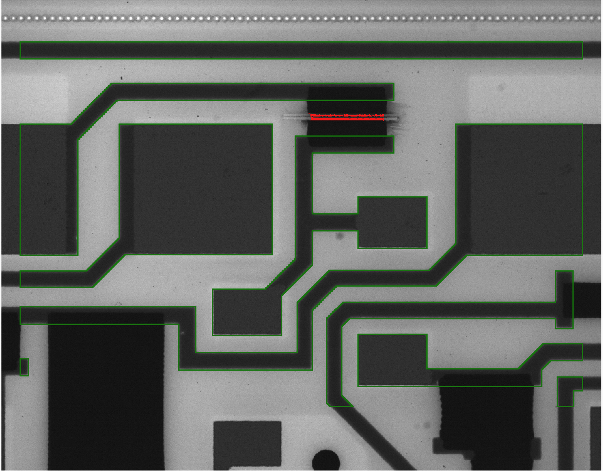

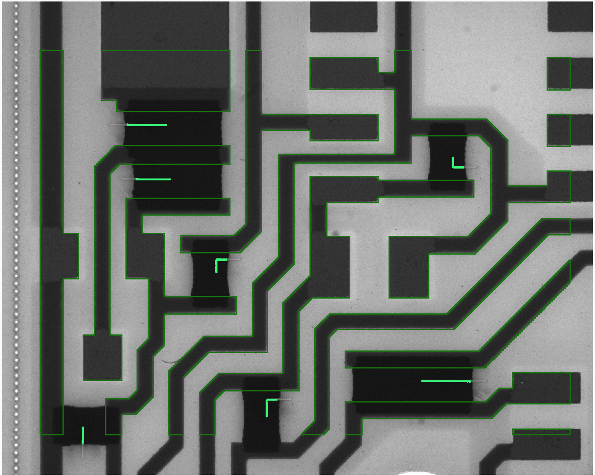

According to the set algorithms parameters, all the laser cut trimms are inspected and evaluated. The left image shows trimms that are detected as good and the trimmed area that was identified. The right image shows two trimms that are too close to eachother as well as having completely cut the resistor in two, this resistor is rejected and the system reports the defect, logs the data and stores the information. This information can now be used to set up the trim parameters differently or for quality control to ensure that only functioning circuits leave the facility.