Print Shift Inspection

Automatic print shift offset calculation

Electronic components become smaller and smaller with an increasing demand of high precision in the manufacturing process to satisfy requirements in modern applications, such as 5G networks for mobile telecommunication or in the automobile industry.

To help you meet these demands, Stratus Vision’s AOI software SPIN, for the Automatic Optical Inspection of ceramic hybrids, LTCCs, HTCCs, interposers and other substrates, can now not only detect various defects, but also calculate the print shift of inspected substrates. Therefore, SPIN is no longer just for detecting defect substrates, but will also improve your print accuracy, resulting in less defects and higher product quality.

Get more information about our Print Shift Inspection from one of our Consultants

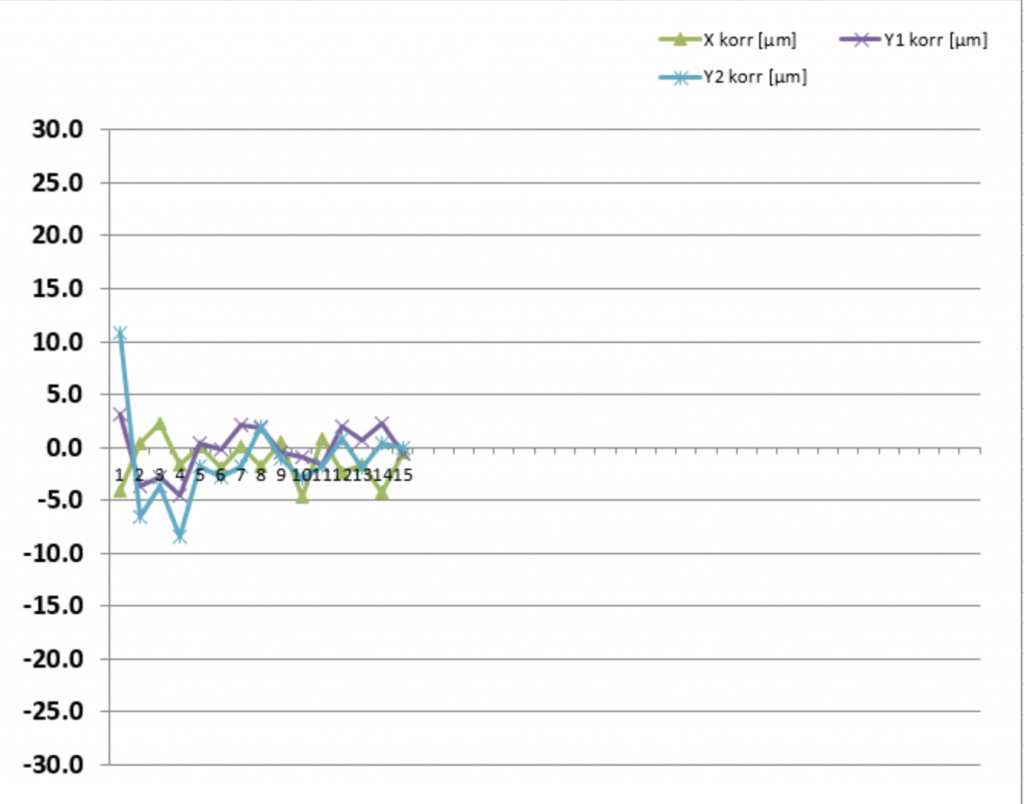

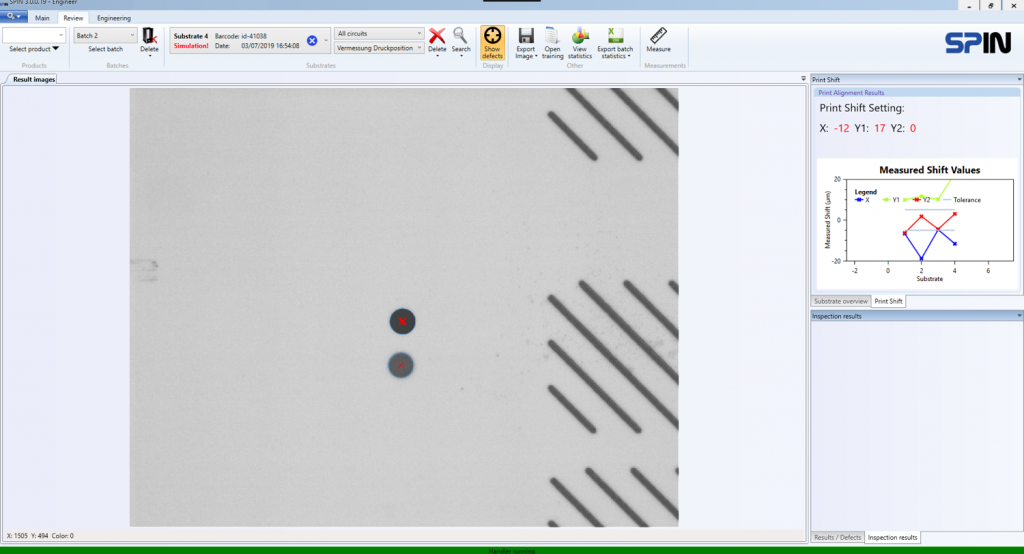

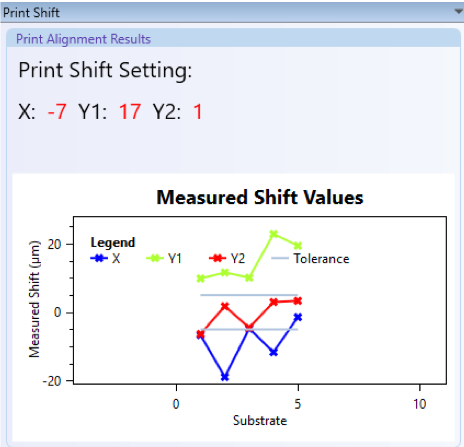

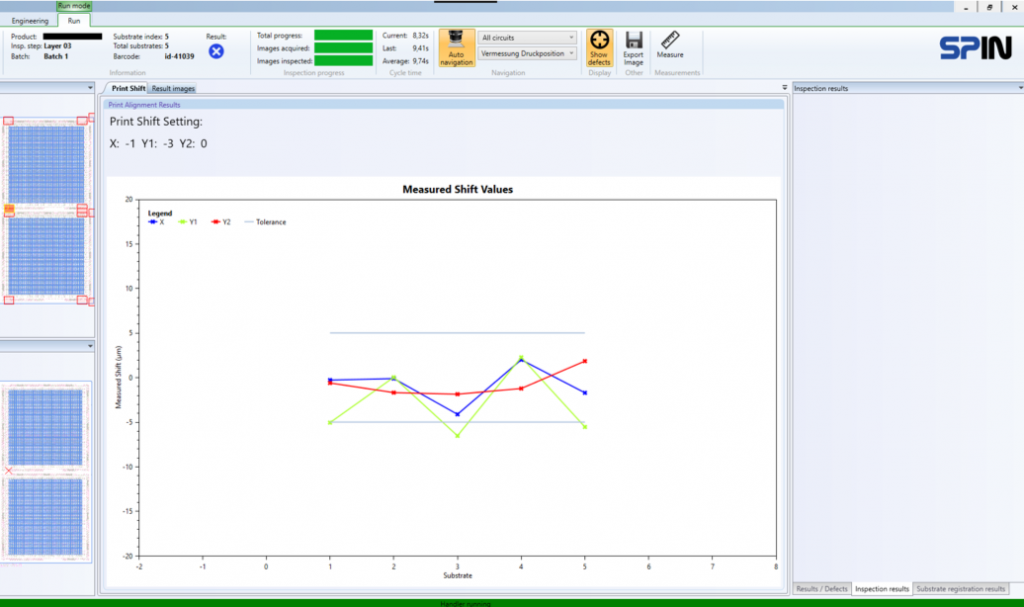

When a part is inspected by one of our inline or offline machines, the print shift is calculated during the search for defects. Our software immediately displays the current print shift for the operator, and signals if any value is outside the tolerance limits. The operator can then immediately adjust the printer settings to compensate for the current print shift. Alternatively an integration to the print system is available so the values are transferred automatically and a closed loop system is therefore integrated. SPIN also displays a graph of the most recent print shifts, to see if a recent print shift tolerance violation is just the result of a single sprint shift abnormality that can be ignored or a steady change in the print shift that requires adjustments.

The print shift calculation works in 3 steps. First, 4 alignment holes in the substrate are located and their position is compared to their position in the entered CAD data. With this information SPIN can calculate the exact position and orientation of the substrate. In the second step, between 4 and 16 printed alignment dots are located on the substrate and also compared to their ideal position from the CAD data. With this information SPIN can calculate the print shift of the print on the substrate. To prevent individual spikes in the print shift from causing constant readjustments of the printer, the displayed print shift is a weighted average of the most recent results, configurable by the user. Together with the adjustable shift threshold, at which the operator is notified that a printer adjustment is necessary, the system can be fully adjusted to the user’s needs.

Finally, SPIN’s review mode allows the user to view the inspection and print shift results at a later date. This replays the print shifts exactly as they happened, displayed in the same graph and with weighted average as seen during inspection. This allows for a reconstruction of the print shift over a longer timeframe.

The automatic print shift calculations in SPIN must only be set up once, and will help to reduce defects and increase the quality of printed parts, through quick feedback about possible misalignments in print layers caused by print shift and the display of necessary adjustments to counteract it.